-

Give us a call 0592 6536915

-

Email us sophia@fzolink.com

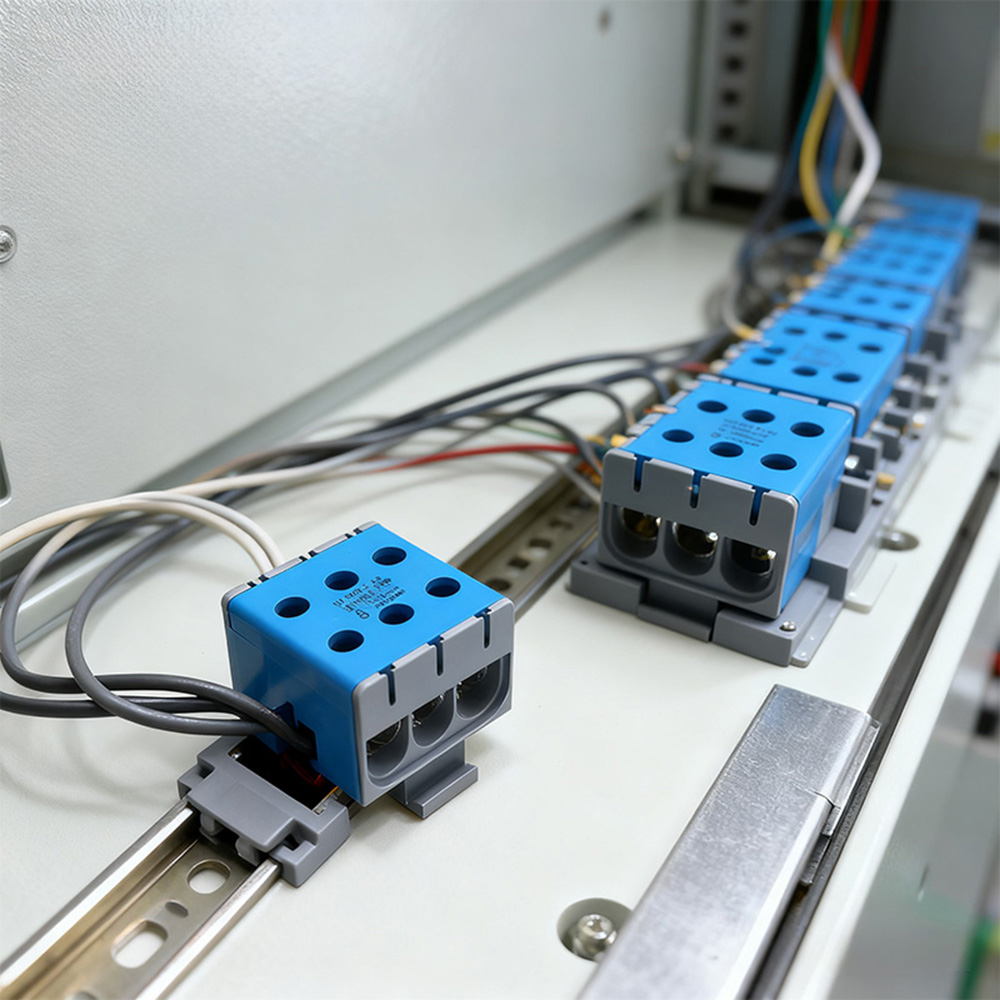

What exactly are DIN rail terminals? A DIN rail terminal block is a junction point for connecting, terminating, and distributing electrical wires in control panels, electrical cabinets, or other electrical systems.

In electrical engineering, DIN rail terminal blocks are fundamental components that play a pivotal role in establishing secure and efficient electrical connections. These terminal blocks are specifically designed to be mounted on DIN (Deutsches Institut für Normung) rails, They provide a convenient and organized way to manage multiple electrical connections in a compact, accessible manner. By using DIN rail terminal blocks, electrical engineers and technicians can simplify the wiring process, enhance connection reliability, and facilitate maintenance and troubleshooting.

Browse All DIN Rail Terminal Blocks

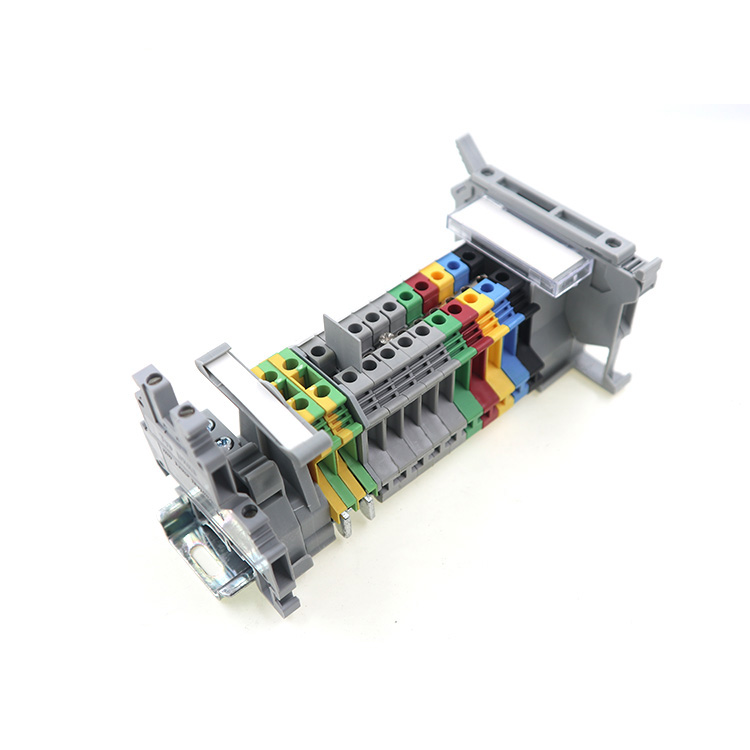

Single-level terminal blocks:The most common type with one row of connectors, suitable for simple wiring tasks.

Double-level terminal blocks: Feature two rows of connections, offering compact wiring solutions for space-constrained applications.

Triple-level terminal blocks: Have three rows of connections, providing higher wiring density for complex control systems requiring efficient multi-connection management.

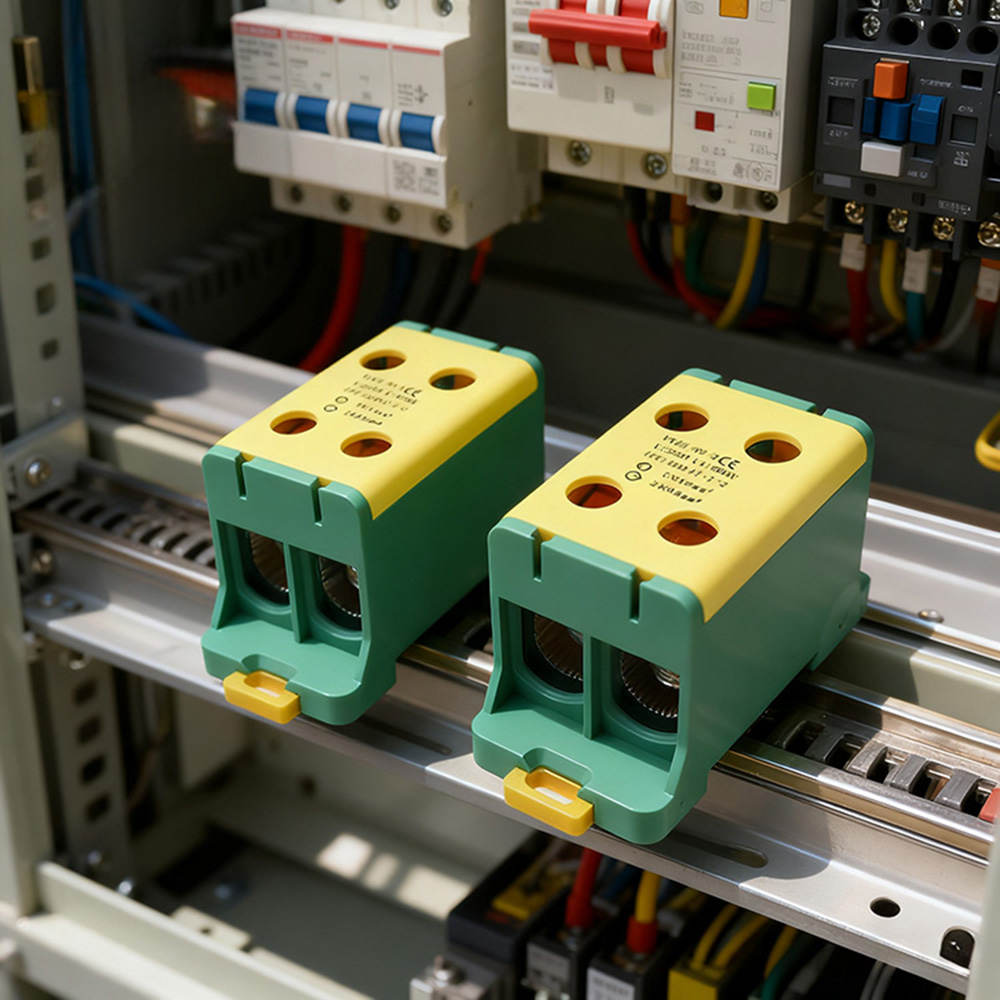

Ground terminal blocks: Specifically designed to provide safe grounding points for electrical systems, usually marked with green-yellow colors for easy identification.

Screw-termination terminal blocks: A traditional connection method that fixes wires by tightening screws. Suitable for various wire sizes and types, ensuring secure and reliable connections.

Spring-cage termination terminal blocks: Use spring mechanisms to fix wires, enabling quick and tool-free installation. Ideal for applications requiring frequent connection changes.

Plug-in termination terminal blocks: Allow direct insertion of solid or stranded wires with ferrules. Labor-saving and ensuring firm connections, suitable for high-density wiring.

Fused terminal blocks: Equipped with one or more fuses in a special hinged section, providing overcurrent protection. Commonly used for safeguarding sensitive devices like sensors and relays, often with LED indicators to show fuse status (blown or intact).

Non-fused terminal blocks: Offer reliable connection points without built-in fuse protection. Suitable for circuits where overcurrent protection is already provided elsewhere.

Busbar terminal blocks: Used in switchgear and panels, featuring a simple structure and compact size. Enable potential distribution on 10x3mm busbars.

Stud terminal blocks: Sturdy in structure, requiring ring terminals to be installed on wires before tightening with hex nuts. Designed specifically for safe power distribution in the electrical industry.

The core purpose of DIN rail terminal blocks is to provide standardized and safe wiring solutions for electrical systems. They adapt to various scenarios requiring organized connections and power/signal distribution, covering both industrial and civil electrical equipment.

Main uses include:

Industrial automation equipment: Such as PLC control cabinets, frequency converters, and servo systems. Used to connect power supplies, sensor signals, and actuator lines, realizing control loop wiring.

Electrical control cabinets/distribution boxes: In strong and weak current cabinets of buildings and factories, distribute power, connect branch lines, and organize wiring of main circuits and control circuits.

Instruments and testing equipment: Connect detection probes and signal cables to ensure stable transmission of precision signals, while facilitating equipment debugging and maintenance.

Rail transit and new energy equipment: Such as subway control boxes, photovoltaic inverters, and energy storage equipment. Used for high-reliability power distribution and line transfer.

Building automation systems: Wiring of central air conditioning, security monitoring, and lighting control systems to achieve centralized control and signal linkage.

Marine and automotive electronics: Adapt to wiring needs in harsh environments. Ensure electrical stability in vibrating conditions through firm connections and insulation protection.

The core of selecting suitable DIN rail terminal blocks is to match electrical parameters, termination methods, and application scenarios, while considering installation space and safety requirements. Follow these key dimensions to screen step by step:

Match rated voltage/current: Based on the circuit voltage (e.g., 24V DC, 220V AC) and maximum operating current, select terminal blocks with parameters not lower than actual needs to avoid overload heating.

Adapt to wire specifications: Confirm the type of wires to be connected (solid/stranded) and wire gauge (e.g., 0.5-2.5mm²). The terminal block’s wiring holes must match the wire gauge to ensure a secure connection.

Screw termination: Suitable for fixed wiring and scenarios without frequent modifications. It has strong compatibility, adapts to various wire gauges, but requires tool operation.

Spring-cage termination: Tool-free and fast wiring, ideal for scenarios with frequent maintenance or limited space. It offers high wiring efficiency but slightly higher cost.

Plug-in termination: Requires ferrules for use, suitable for high-density wiring and quick plug-in scenarios. It has strong stability and is often used in automation equipment.

Rail compatibility: Prioritize models compatible with 35mm standard DIN rails to ensure installation versatility.

Wiring density: For limited space, choose double-level/triple-level terminal blocks to increase the number of connections per unit space; single-level terminal blocks are sufficient for general scenarios, enabling neater wiring.

Combined functions: Select busbar terminal blocks for potential distribution, fused terminal blocks for overcurrent protection, and dedicated ground terminal blocks (green-yellow marked) for grounding protection.

Environmental protection: For humid, dusty, or outdoor scenarios, choose terminal blocks with higher protection ratings (IP rating, e.g., IP65) to avoid insulation failure.

Anti-interference/vibration: For vibrating environments such as industrial equipment and rail transit, spring-cage or plug-in termination is more anti-loosening than screw termination; for strong electromagnetic environments, select materials with excellent insulation performance (e.g., PA66).

Safety certification: Prioritize products complying with international standards such as IEC and UL to ensure electrical safety compliance.

Labeling convenience: Choose terminal blocks with clear labeling positions or removable nameplates for easy later maintenance.

Cost balance: Opt for screw termination (cost-effective) for regular scenarios; consider spring-cage or plug-in termination only for special needs (fast wiring, high reliability).

Do not prioritize low cost over rated parameters: Selecting terminal blocks with current/voltage lower than actual requirements may cause overload heating or safety hazards.

Do not ignore wire type matching: Stranded wires used with screw-termination blocks require ferrules to prevent loosening or poor contact.

The core process of using DIN rail terminal blocks involves "Confirm terminal specifications → Turn off circuit power → Install terminals onto the guide rail → Wiring → Check wiring for secure connection → Affix labels for easy future maintenance."

The specific operating steps are as follows:

Confirm the terminal block type and specifications, then turn off the power to the corresponding circuit. Verify no voltage with a tester to avoid electric shock.

Critical safety note: Never wire or install terminal blocks with the circuit powered on.

Align the terminal block’s clips with the rail’s grooves, then slide it onto the rail from one end or press firmly until a "click" confirms it’s locked in place. For multiple terminal blocks, install them sequentially, ensuring they fit tightly together. Secure both ends with mounting brackets if needed to prevent loosening.

Recommendation: 35mm standard DIN rails are universally compatible with most terminal block models.

Screw Termination: Strip 6-10mm of the wire insulation (avoid excessively exposed conductors). Loosen the terminal screw, insert the stripped conductor, and tighten the screw with moderate force.

Spring-Cage Termination: Strip the wire insulation, then insert the conductor directly into the connection hole—the spring will automatically clamp and secure it. To remove, use a dedicated tool or screwdriver to press the spring release tab while pulling the wire out.

Plug-In Termination: First, crimp the appropriate ferrule onto the wire, ensuring a tight fit between the ferrule and conductor. Insert the ferrule directly into the terminal’s plug-in port until it locks in place.

Gently tug each wire to confirm secure connections. Insulate any exposed conductors with tape to prevent short circuits. Attach labels to the terminal blocks or rail to indicate the purpose of each terminal, facilitating easy maintenance.

Do not connect multiple wires to a single terminal unless specified as compatible by the manufacturer.

Distinguish between positive/negative poles and high/low voltage circuits during wiring to prevent equipment damage or safety hazards.

In humid or vibrating environments, use terminal blocks with appropriate protection ratings and inspect connections regularly.

Prepare necessary tools in advance: Wire strippers, screwdrivers, voltage testers, and ferrules (for plug-in/screw-termination with stranded wires).

Sliding link terminal blocks are a type of DIN rail terminal block designed with movable conductive links (sliders) to simplify potential distribution and circuit bridging.

The key component is a sliding conductive slider (usually metal) installed on the terminal block.

Without rewiring, sliding the link along the terminal row electrically connects multiple adjacent terminals.

They maintain the basic wiring function of standard terminal blocks while adding quick bridging capabilities.

Save wiring time: Eliminate the need for jumper wires between terminals, reducing manual connection work.

Flexible configuration: Adjust the bridging range by sliding the link, adapting to dynamic circuit changes.

Neat wiring: Avoid messy jumper wires, keeping the cabinet interior organized and easy to maintain.

Power distribution in control cabinets: Distribute a single power supply (e.g., 24V DC) to multiple control terminals.

Signal synchronization: Bridge signal lines in PLC systems or sensor networks to ensure consistent potential.

Temporary circuit testing: Quickly establish or disconnect bridging connections during equipment commissioning.

Whether you’re designing a control panel or maintaining electrical systems, understanding DIN rail terminal blocks is essential for safe and efficient wiring. These components have firmly established themselves as an essential part of modern electrical systems, with an irreplaceable role in creating reliable electrical connections, distributing power, and transmitting signals. From simple residential electrical wiring to complex industrial automation systems, DIN rail terminal blocks are the unsung heroes ensuring the smooth operation of electrical equipment.

As we look to the future, the continuous development of DIN rail terminal blocks—driven by trends such as miniaturization, intelligence, new materials, and environmental friendliness—will further enhance their performance and expand their applications. These advancements will enable them to meet the evolving needs of various industries and contribute to the development of more efficient, reliable, and sustainable electrical systems. Whether in the pursuit of technological innovation in smart factories, the development of renewable energy sources, or the improvement of everyday electrical appliances, DIN rail terminal blocks will continue to play a crucial and ever-evolving role in the world of electrical engineering.

Looking for high-quality DIN rail terminal blocks that meet IEC/UL standards? Browse our product range or contact our team for customized solutions tailored to your application needs.